SCARA Robot Pick Place Systems

Price 80000 INR/ Set

SCARA Robot Pick Place Systems Specification

- Load Capacity

- Up to 10 kg

- Screen Size

- 7 inch HMI

- Automation Grade

- Automatic

- Processor Type

- Industrial Microcontroller

- Features

- High Precision, High Repeatability, Fast Cycle Time

- Phase

- Single Phase

- Application

- Pick and Place, Assembly, Packaging

- Mounting Type

- Floor/Bench Mount

- Speed Range

- 03000 mm/sec

- Control Type

- PLC Based

- Weight

- 45 kg

- Drive Type

- Servo Motor Drive

- Sensor Type

- Proximity, Position, Vision Sensors

- Frequency

- 50/60 Hz

- Remote Control

- Yes

- Cable Length

- 3 meters

- Connectivity Type

- Ethernet, USB

- IP Rating

- IP54

- Material

- Aluminum Alloy Structure

- Power

- 750 W

- Temperature

- 0C to 45C

- Voltage

- 220V AC

- Programming Interface

- Windows-Based GUI

- Lubrication

- Maintenance Free

- Axis

- 4 Axis (SCARA)

- Safety

- Emergency Stop, Safety Light Curtain Compatible

- End-effector

- Vacuum Gripper / Mechanical Gripper

- Operation Mode

- Manual/Automatic/Teaching Pendant

- Repeatability

- 0.02 mm

- Work Envelope (Reach)

- 400 mm Radius

- Noise Level

- <65 dB

- Cycle Time

- 0.45 seconds/operation

- Compliance Standard

- CE Certified

- Working Humidity

- 1080% RH (non-condensing)

About SCARA Robot Pick Place Systems

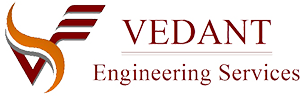

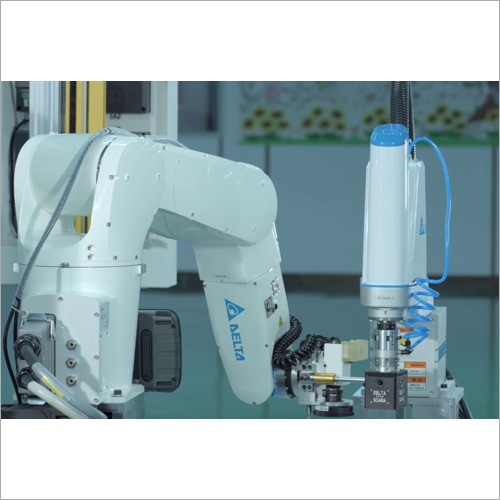

Industrial robots are programmed to automatically accomplish applications such as screw driving, dispensing, soldering, palletizing, assembly, and pick and place. Due to their flexibility and adaptability, robots are able to optimize production and enhance productivity for smart manufacturing. Delta is continuously developing new types of robots for all kinds of applications to fulfill industry demands, and to realize Automation for a Changing World

They can be applied in a wide range of industries including consumer electronics, electrical /electronics, rubber and plastic, metal fabrication and for processes such as screw driving, dispensing, assembly, load and unload, soldering, transporting and packaging .

High Precision & Fast Operation

Engineered for efficiency, the SCARA Robot delivers high repeatability (0.02 mm) and a fast cycle time of only 0.45 seconds per operation. The servo motor drive combined with proximity, position, and vision sensors ensures accurate placement in diverse industrial settings. Its 10 kg load capacity suits various pick-and-place, packaging, and assembly tasks.

User-Friendly Programming & Connectivity

Programming and monitoring the robot are straightforward with the Windows-based GUI and 7-inch HMI touchscreen. Operators can utilize multiple connectivity options, including Ethernet and USB, for seamless integration with factory systems. Single-phase 220V AC operation simplifies installation and enhances compatibility across facilities.

Robust Build & Comprehensive Safety

Crafted from durable aluminum alloy and rated IP54, the system withstands industrial environments. Integrated safety features include emergency stop and compatibility with safety light curtains, ensuring the safety of operators while maintaining efficient workflow. Maintenance-free lubrication further reduces downtime and operational costs.

FAQs of SCARA Robot Pick Place Systems:

Q: How is the SCARA Robot Pick & Place System programmed and monitored?

A: The robot utilizes a user-friendly Windows-based graphical interface accessible via a 7-inch HMI screen. Operators can program, teach, and monitor operations either manually, automatically, or using the teaching pendant for flexible workflow management.Q: What applications are best suited for this SCARA robot system?

A: Designed for high-speed, high-precision automation, this robot excels in pick-and-place, assembly, and packaging tasks. Its robust design and versatile gripper options make it ideal for electronics, automotive, pharmaceutical, and consumer goods industries.Q: When is preventive maintenance required for this robot?

A: Thanks to its maintenance-free lubrication system and durable components, the robot requires minimal preventive maintenance. Routine inspections for safety features and system checks are recommended to ensure continuous optimal performance.Q: Where can the SCARA Robot be installed?

A: The system supports both floor and bench mounting, allowing integration into a variety of production line setups. Its IP54 rating safeguards it in environments with dust or limited water exposure typically found in manufacturing plants across India.Q: What safety features are incorporated in this SCARA robot?

A: Safety is addressed through an emergency stop function and compatibility with safety light curtains. These measures reduce risks to operators, ensuring compliance with CE standards during both setup and routine operation.Q: How does this robot benefit industrial automation processes?

A: With high precision, repeatability, and speed, the robot increases throughput and consistency while reducing human error and labor fatigue. Its centralized PLC-based control and remote operation capabilities further streamline production and enhance operational flexibility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Robot Category

Delta Industrial Robot

Price 50000 INR / Set

Minimum Order Quantity : 1 Set

Usage : Industrial

Material : Stainless Steel

Warranty : 1 Year

Color : White

SCARA Robot

Price 50000 INR / Set

Minimum Order Quantity : 1 Set

Usage : Industrial

Material : Stainless Steel

Warranty : 1 Year

Color : White

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free