Horizontal Tensile Testing Machine

Horizontal Tensile Testing Machine Specification

- Application

- Tensile testing of metallic and non-metallic materials

- Measuring Range

- 0-10000 N

- Humidity

- 35%RH - 85%RH

- Gas Pressure

- 0.4-0.7 MPa

- Power Supply

- 220V AC, 50Hz

- Resolution

- 0.01 N

- Temperature

- 5C to 35C

- Display Type

- Digital LCD Display

- Test Range

- 0-10 kN

- Interface Type

- RS232/USB

- Specimen Size

- Variable, up to 300 mm width

- Mounting Type

- Floor mounted

- Frequency

- 50 Hz

- Features

- Adjustable test speed, Digital display, Overload protection

- Max Height

- Approx. 1200 mm

- Equipment Type

- Horizontal Tensile Testing Machine

- Accuracy

- 1%

- Response Time

- 1 sec

- Port Size

- 1/4 inch

- Number of Specimens

- 1

- Operating Voltage

- 220V

- Automation Grade

- Semi-Automatic

- Usage

- Material strength testing

- Capacity

- 10 kN max

- Machine Weight

- Approx. 220 Kg

- Test Speed

- 20-500 mm/min adjustable

- Test Width

- Up to 300 mm

- Test Stroke

- 600 mm

- Control Mode

- Digital/Automatic

About Horizontal Tensile Testing Machine

We are the well known manufacturers of a high quality of products such as the Computerized Horizontal Tensile Testing Machine which is used by the laboratories, material manufacturers and other industries. These products find very accurate measurements and they are very reliable in their readings.

Features:

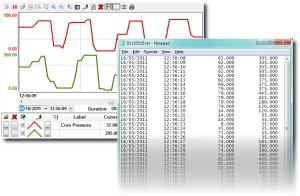

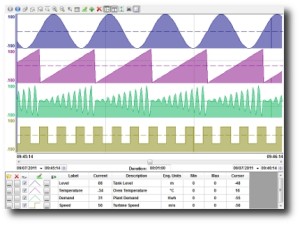

- PLC Smart Control

- High Precision Sensors

- Graphical Display of load and other parameters.

- Special Software Package for Testing

- Test Report Generation & Printing

- High loading accuracy & infinitely variable straining speeds to suit a wide range of materials.

- Robust loading frame, Simple controls & easy to operate.

- Special Accessories like a Extra Bed length, Extra Ram stroke, Various special grips / attachments / fixtures as per sizes / shapes of specimens, Load-stabilizer (at extra cost) can be provided to suit special application.

- Adequate safety devices for safe operation.

Software Package :

The tester offers a host of software features that allows programming of all parameters, operational control and real-time display of the on-going test. This software package allows the operator to conduct a wide range of tests with an almost limitless array of test parameters and displayed test information.

If there is something, which is not listed, please contact us to discuss your requirements. We can tailor make machines and programs to our customeras requirements.

We have developed following horizontal tensile testing machines :

- 100 Ton (1000 kN)

- 120 Ton (1200 kN)

- 150 Ton (1500 kN)

- 200 Ton (2000 kN)

- 75 Ton (750 kN)

- 50 Ton (500 kN)

- 60 Ton (600 kN)

- 2- 15 Ton

We are one of the renowned Horizontal Tensile Testing Machine manufacturers from nashik.

Precision Strain Gauge Load Cell

The machine integrates a strain gauge load cell with 1% accuracy and a resolution of 0.01 N, ensuring highly reliable force measurements during testing. This enables users to precisely evaluate tensile properties for a broad range of specimen sizes and materials, enhancing research and quality control.

Advanced Safety Features

Emergency stop and over-travel limiters are built-in to safeguard users and prevent equipment damage during operation. These features provide immediate response to unsafe conditions and help maintain a controlled testing environment, ensuring compliance with lab safety standards.

Digital Control and Data Management

Equipped with a digital LCD display and compatible with PC software via RS232/USB, the machine allows seamless data capture, real-time monitoring, and automatic control. This facilitates efficient analysis, reporting, and traceability of tensile test results.

FAQ's of Horizontal Tensile Testing Machine:

Q: How does the Horizontal Tensile Testing Machine ensure precise material strength testing?

A: The machine utilizes a precision strain gauge load cell with 1% accuracy and 0.01 N resolution, combined with a servo motor-driven crosshead for consistent and repeatable test speeds. This enables high reliability in tensile testing results for various material specimens.Q: What safety mechanisms are featured in this testing machine?

A: Key safety mechanisms include an emergency stop button and an over-travel limiter, which provide immediate intervention in case of abnormal operation or excessive movement, ensuring the safety of both users and equipment.Q: When is it suitable to use this equipment for tensile testing?

A: This machine is ideal for tensile testing of both metallic and non-metallic materials whenever compliance with ASTM D638 and ISO 527 standards is required, especially in quality control, R&D, and manufacturing processes.Q: Where can the tensile testing machine be installed?

A: The machine is designed for floor-mounted installation and fits easily into laboratories, manufacturing facilities, and material testing centers, supporting operational environments with humidity between 35% and 85% and temperatures from 5C to 35C.Q: What is the testing process using this machine?

A: Specimens are secured using manual screw action grips, followed by adjustable test speed setup. The digital control system manages the testing process, and force data is recorded in real-time for detailed analysis, with results displayed digitally and exportable via PC software.Q: How does digital control benefit material testing operations?

A: Digital control combined with automatic data output and adjustable test speeds streamlines the testing workflow, reducing human error and facilitating accurate, repeatable measurements, while simplifying data management for compliance and reporting.Q: What are the main usage advantages for Indian manufacturers and suppliers?

A: This machine offers versatility for different materials, complies with major international standards, and delivers fast, accurate results with minimal operating noise (60 dB) and user-friendly digital controls, making it a valuable asset for material strength testing applications in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS