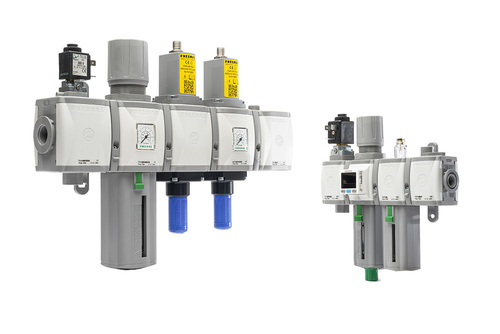

FRL UNIT

Price 1000 INR/ Piece

MOQ : 1 Piece

FRL UNIT Specification

- Automation Grade

- Manual

- Drive Type

- Pneumatic

- Connectivity Type

- Threaded

- Weight

- Approx. 500g

- Application

- Compressed Air Filtration, Lubrication and Regulation in Pneumatic Systems

- Control Type

- Regulator

- IP Rating

- IP54

- Sensor Type

- Pressure Gauge

- Features

- Water Separator, Lubricator, Pressure Regulator

- Load Capacity

- 10 Bar (Max. Operating Pressure)

- Mounting Type

- Inline/Panel Mount

- Material

- Aluminum Alloy

- Power

- Manual Operation

- Temperature

- 5C to 60C

About FRL UNIT

AIRPLUS SERIES MANIFOLD UNIT Modular system, flange coupling plug-n-play configuration Aluminum/Technopolymer |

AIRPLUS SERIES SAFETY Supply and discharge valve single Supply and discharge valve double |

AIRPLUS SERIES COMPLEMENTARY MODULES Progressive start-up valve Air intake Pressure switch Air intake with pressure gauge |

SHUT OFF VALVES 3/2 N.C. shut off valve Aluminum/Technopolymer |

LUBRICATORS Oil mist lubricator with flow rates up to 16000 Nl/min and connections from 1/8 to 1 Aluminum/Technopolymer |

AIRPLUS SERIES REGULATION Filter regulators Regulators Piloted pressure regulators Pressure regulators for manifold |

AIRPLUS SERIES FILTRATION Filters Coalescing filters Oil removal filters Carbon filters |

S1700 STEEL LINE SERIES SIZE 4 Inox air service units Size 4 3/4 NPT 1 NPT G1 |

S1700 STEEL LINE SERIES SIZE 3 Inox air service units Size 3 1/4 NPT 1/2 NPT G1/2 |

S1700 STEEL LINE SERIES SIZE 2 Inox air service units Size 2 1/4 NTP 3/8 NPT G1/4 |

PRESSURE BOOSTER, P+ SERIES In some cases the force generated by a pneumatic actuator is not sufficient to carry out its required function. To overcome this problem it is then necessary, where possible, to either increase the working pressure or use a larger bore actuator providing it will fit within the structure of the machine. |

PRESSURE BOOSTERS It is not unusual that, during some applications the thrust generated by a pneumatic cylinder is not sufficient for the specific purpose it has been designed for. |

MINIATURIZED PROPORTIONAL PRESSURE REGULATOR Modern industrial applications constantly require more sophisticated and better performing pneumatic components . Flexibility and adaptability are key factor when designing a machine. The possibility to change the application parameter during operation such as for example the speed of a cylinder or the force generated by a rotary actuator are beneficial to the designer. In the past it was necessary to design complicated pneumatic circuits based on pneumatic logic elements which required a lot of space and complicated set up, today, thanks to the electronic proportional regulators such operations are extremely easy to achieve and offer even more flexibility. |

ELECTRONIC PROPORTIONAL REGULATOR Modern industrial applications require high performance pneumatic components. Taking cylinders and rotary actuators as our example, it is necessary to be able to control the parameters that determine their speed, thrust and torque. |

AIR SERVICE UNITS SIZE 4 G1 The modular air service units groups of the size 4, as the other size, allow a wide selection of combinations. |

Efficient Modular Assembly

This FRL UNITs modular design simplifies installation and allows for adaptable configurations within various pneumatic systems. Its threaded, inline or panel mounting capabilities ensure compatibility with a wide range of setups, making it an ideal choice for factories, workshops, and industrial applications.

Advanced Filtration and Lubrication

Equipped with a polycarbonate bowl and 40-micron filtration accuracy, the unit effectively removes water and particulates, safeguarding downstream equipment. The oil mist lubricator maintains proper lubrication, reducing wear and extending the lifespan of pneumatic tools and cylinders.

Reliable Regulation and Monitoring

A built-in pressure gauge provides clear, real-time feedback for manual regulation up to 10 Bar, facilitating safe and efficient operation. The aluminum alloy body coupled with an IP54 rating offers robust protection against dust and water, ensuring long-term reliability.

FAQs of FRL UNIT:

Q: How does the FRL UNIT improve pneumatic system performance?

A: The FRL UNIT enhances performance by filtering out water and particulates, regulating air pressure with its integrated pressure gauge, and delivering consistent lubrication via the oil mist lubricatorresulting in smoother, less wear-prone operation for pneumatic equipment.Q: What is the recommended process for installing this FRL UNIT?

A: Installation involves mounting the unit inline or on a panel using its threaded 1/4" BSP ports. Ensure compatibility with your systems air supply, securely connect the unit, and verify that all connections are sealed before manual operation begins.Q: When should the manual drain be operated on the FRL UNIT?

A: The manual drain should be operated regularly or whenever the pressure gauge indicates possible excess moisture accumulation. This helps prevent water buildup and maintains optimal filtration efficiency in pneumatic circuits.Q: Where is this FRL UNIT commonly used and distributed in India?

A: This unit is widely utilized in industrial environments such as factories, manufacturing units, workshops, and equipment service centers. It is available through dealers, distributors, suppliers, traders, and wholesalers across India.Q: What are the specific benefits of the modular assembly and oil mist lubricator?

A: The modular assembly allows easy customization or replacement of individual components, while the oil mist lubricator ensures proper lubrication of downstream devices, minimizing maintenance needs and enhancing overall equipment longevity.Q: How does the pressure gauge and regulator ensure safe usage?

A: By providing direct air pressure readings, the pressure gauge allows for precise manual regulation, helping users maintain safe operating pressures up to 10 Bar and prevent possible system overload or damage.Q: What maintenance is required for optimal FRL UNIT operation?

A: Routine maintenance includes periodically draining accumulated water, rechecking lubricant levels, inspecting the polycarbonate bowl, and ensuring all manual controls and connections remain intact to guarantee efficient functionality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pneumatic Products Category

Pneumatic Valves

Minimum Order Quantity : 1 Number

Warranty : 1 Year

Usage : Industrial

Product Type : Pneumatic Valves

Size : Standard

Pneumatic Clamps Grippers

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Usage : Industrial

Product Type : Pneumatic Clamps Grippers

Size : Standard

Material : MS

Pneumatic Fittings

Warranty : 6 months to 1 year based on manufacturer

Material : Brass stainless steel plastic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free